Regular rollers/belt centring stations

Tru-Trac Flat Return Tracker (for bottom belt)

Regular rollers prevent belt misalignment and protect the belt edges. Since regular rollers function efficiently only when the drum casing is clean, rollers are equipped and delivered with dirt-repellent 60° Shore soft rubber.

Our regular rollers can be used with normal and reversing conveyor belts.

Mode of operation:

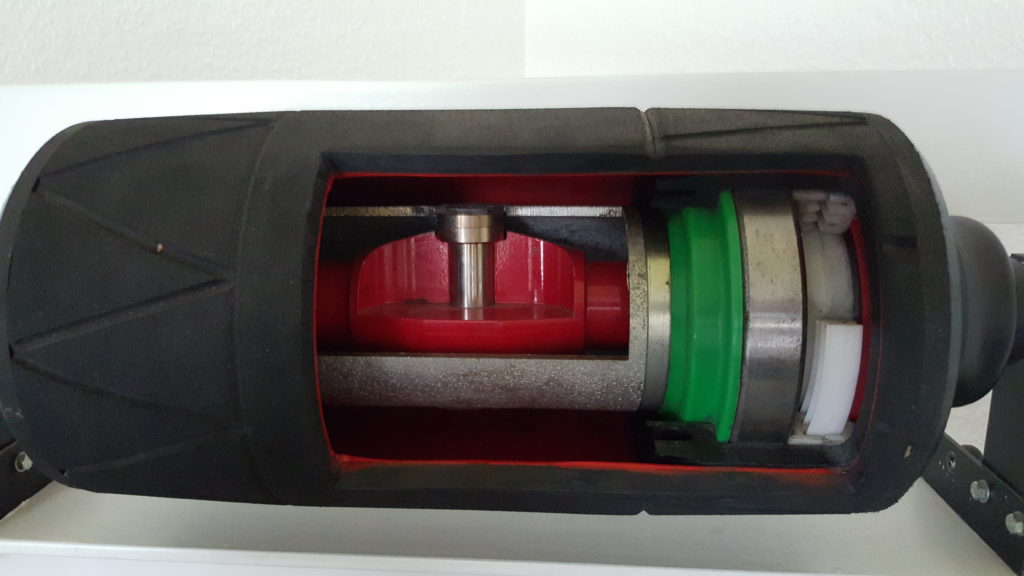

When the conveyor belt is running straight, the longitudinal axle through the roller casing forms a 90° angle to the direction of belt movement. When the belt drifts, the roller casing moves due to the dead weight of the belt, causing a forward motion and returning the belt to its normal position. The roller casing returns to its normal position as soon as the correction is completed. The movement is made possible by a complex ball joint in the centre of the roller, as well as the position of the axle at 90°relative to the conveyor.

Tru-Trac Tapered Trough Tracker (for top belt)

The carrying frame prevents belt misalignment and protects the belt edges. Since the carrying frames only function efficiently when the drum casing is clean, they are equipped and delivered with dirt-repellent 60° Shore soft rubber.

Our carrying frames can be used with normal and reversing conveyor belts.

Mode of operation:

When the conveyor belt is running straight, the longitudinal axle through the roller casing forms a 90° angle to the direction of belt movement.

When the belt drifts, the roller casing moves due to the dead weight of the belt, causing a forward motion and returning the belt to its normal position.

The roller casing returns to its normal position as soon as the correction is completed. The movement is made possible by a complex ball joint in the centre of the roller, as well as the position of the axle at 90°relative to the conveyor.